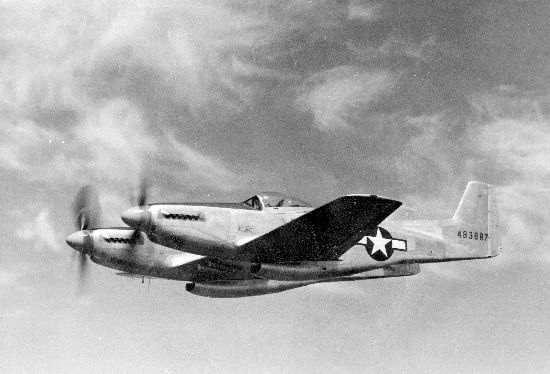

As usual, WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

Wings/Center Section

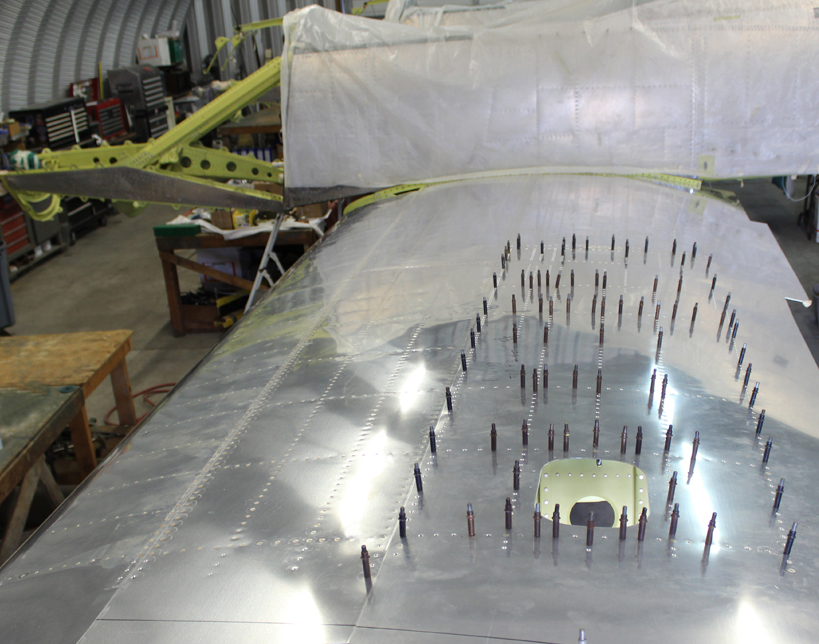

The crew completed the left-hand leading edge and finally riveted it to the forward spar of the left-hand wing.

The remainder of the top inboard skins are now finished through their structural highshear riveting (special collared steel rivets through the wing-attach angles and stringers). On both wings, the crew has three of the four top skins completed along with the two lower inboard skins at the attach angles.

Reilly’s team chose to use the center section as the parent fixture for the attachment of the wing-attach angles, and the riveting of these upper and lower inboard skins to lock everything in place on sweep and dihedral. The two wings will come off during the second week of July and go into their fixtures for final adjustment, and to confirm the washout angles (the downward twist of the outboard section of the wings).

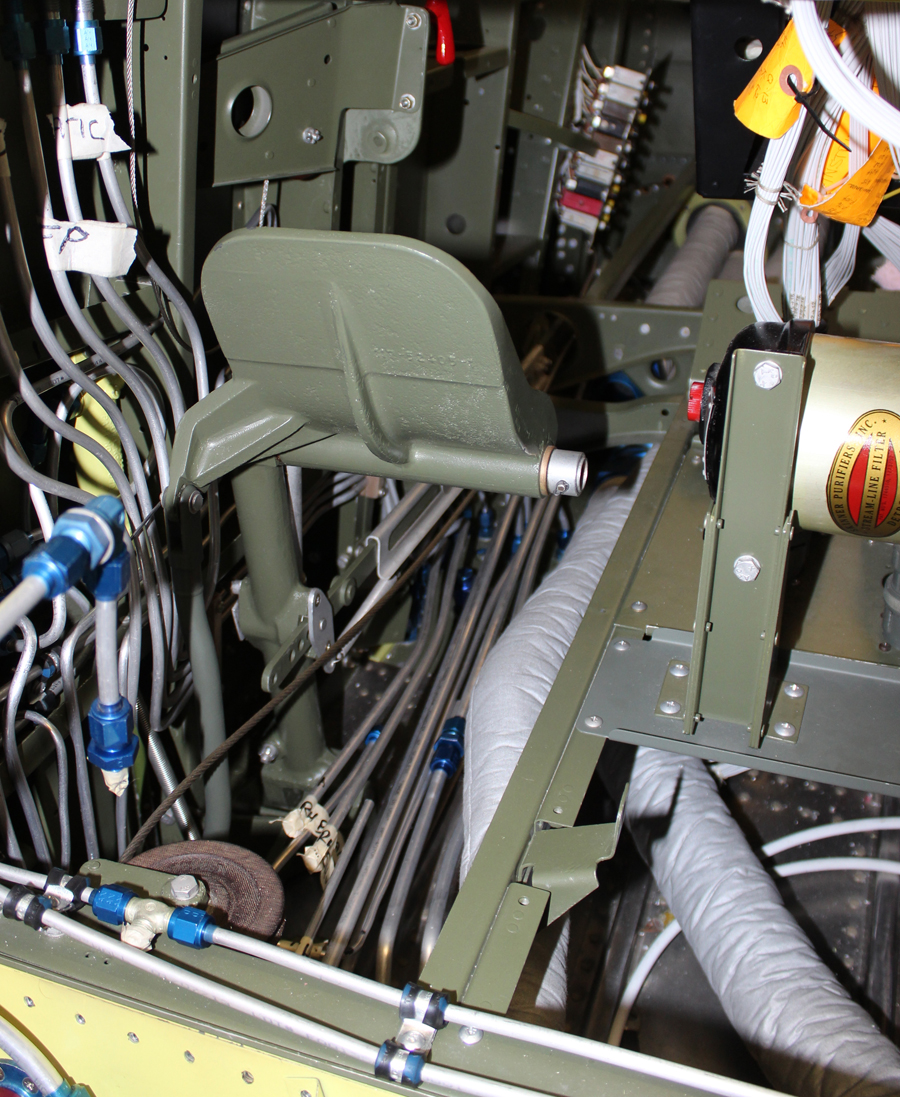

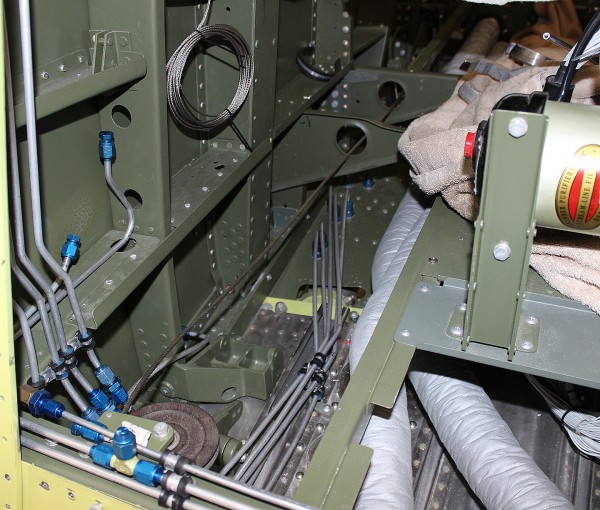

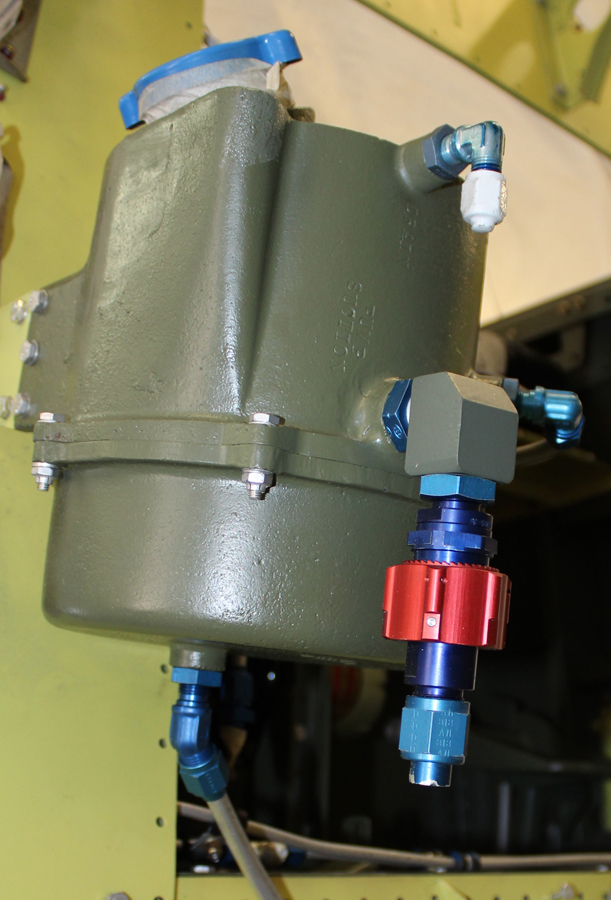

Hydraulic, Instrumentation and Brake Lines

The majority of the lines running along both cockpit floors, and up behind and through each firewall are now finished. Reilly noted that it has been difficult to duplicate the exact routing for each line as most of them were removed in the early 1950s during the disassembly of the fuselage from the center section. Reilly stated that his team was able to accurately determine the routing by locating the through-fittings in the center section floor, and the line mounts on each longeron. The drawings Reilly has only showed the routing for the P-82B and later model fuselages, although a number of them do have the same routing as on the XP-82. The hydraulic tank which mounts to the firewall is now finished, including the fuselage suction feed/return, and pressure lines.

Seats

The team has been restoring the seats, and the question came up about whether to use the original steel armor plate, or replace it with .437 (7/16”) aluminum plate for weight savings. Reilly has two original steel armor plate panels that can be easily welded, surface ground and repainted. He imagines that the decision will hinge upon whether the airplane comes in on its target weight and balance.

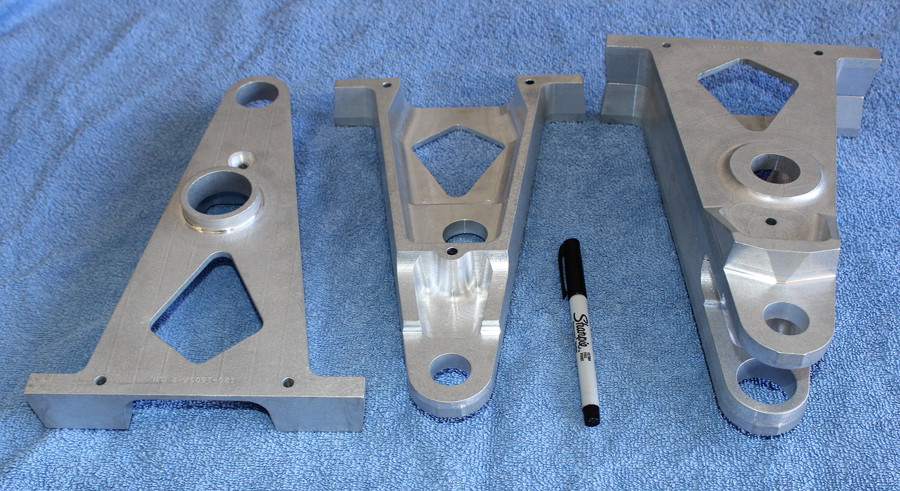

left-hand pair shows the two separated sub-components. (photo via Tom Reilly)

Parts Find

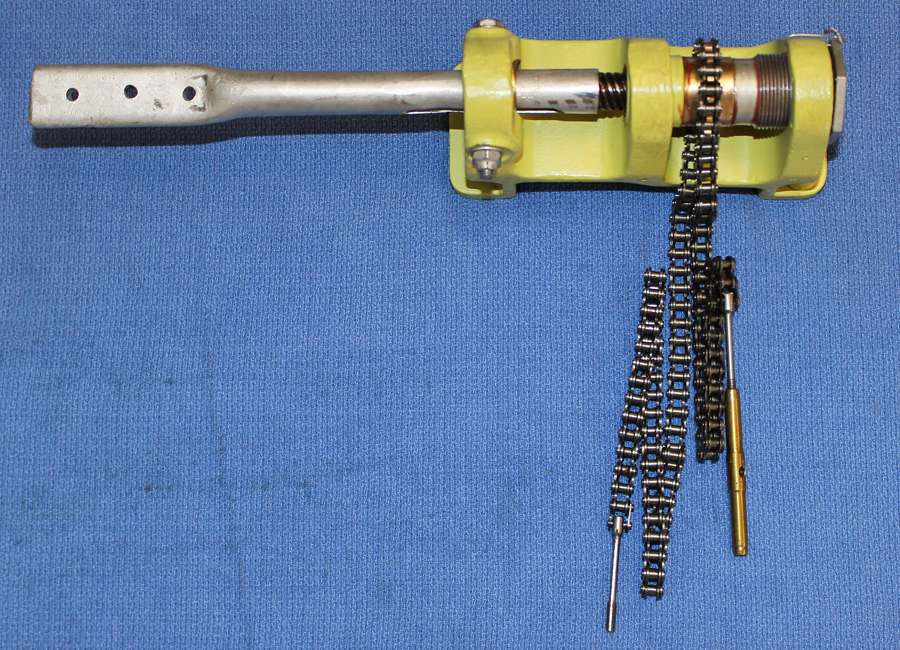

During the first week of June, Tom received a call from a man in Mint Hill, North Carolina, just south of Charlotte. The fellow had purchased a P-40 project from Ms. Janie Odgers, a family member of the late Dick Odgers who originally sold Tom Reilly the remains of a crashed F-82H out of Fairbanks, AK. Odgershad been too ill back in 2008 (when Reilly bought the F-82 parts from him) to travel to Anchorage to complete sorting the F-82 parts from the P-40 parts that he had in his warehouse. Brent VanDervort, whose business is a large hot rod fabrication facility, purchased the P-40 project along with a small cache of F-82 parts. Reilly made a trip to Charlotte in late June to examine what VanDervort had. As it turns out, he had a number of important parts that Reilly’s project was still missing; including four throttle quadrant cable quick disconnects and throttle handle, the pilot’s glare shield gun site mount, one leading edge .50 caliber gun barrel fairing and blast tube, and a number of other small pieces of gold. He declined Reilly’s offer to pay him, and simply said that these parts were supposed to have come to the project six years ago.

Such honesty is a rare commodity, and Reilly stated that, “if anyone is contemplating building a street rod, his company is Fat Man Fabrication, in Mint Hill, NC. One cannot believe the quality and the massive amount of different parts that his factory manufactures for the street rod business. Thank you, Brent!”

throttle quadrant cable quick disconnects that we still needed to complete our cabling. (photo via Tom Reilly)

The XP-82 restoration hangar received a Special Visitor recently. Mr. Jim Sampson, a retired USAF Alaska F-82H pilot from 1946 to 1949, gave the team a very nice visit last week. As Reilly remarked, “Sampson is the youngest and most agile 93- year-old I have ever met in my life. He could remember flight details as if they were yesterday: i.e. air speeds, manifold pressures, climb rates, etc. He was very impressed with our restoration and promises to come back on a regular basis. Thank you, Mr. Sampson, for your USAF service.”

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early August for the next installation following the XP-82′s road to recovery!

Please click HERE for some of our previous updates.

What a great project and only wish you the best in this wonderful endeavor.

Well done guys great project.