(Image Credit: Alan Wilson CC 2.0)

Regular readers will know that The Vulcan team has been undertaking preparatory work ahead of the main flying life extension project to ensure they can continue the more costly elements just as soon as funds are secure. This work (in stages one and two of the wing modification share issue) has already resulted in an accurate 3D computer model of the wings where strengthening is required, and the production of the formers that will be needed on which to shape the complex curved skins – a project being undertaken by Beagle Technology Group in Christchurch, Dorset.

Preparations for Operation 2015 are progressing well, thanks to the generosity of supporters who have purchased the Phase 2 ‘share’. You may remember from previous articles that Vulcan XH558 – now the last airworthy all-British large jet – is almost out of fatigue life.

After initial fears that there was no possible solution, the hard work and imagination of our engineering team and their specialist suppliers has found a way to replicate an original Avro modification for strengthening the critical wing sections where a compound curvature was introduced for the Mk2 aircraft.

In the previous articles we explained how the reinforcing panels will be precisely shaped by craftsmen at Beagle Technology Group using a combination of stretch-forming and English wheeling. The stretch-forming process pulls the aluminium panels over rigid formers that are the shape of the wing section and it is the production of these formers that has occupied the team for the past month.

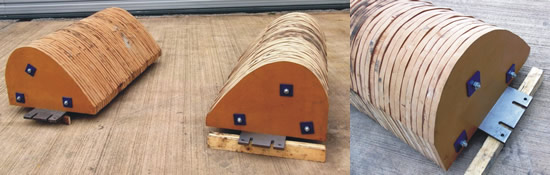

Each of the two formers – one for each wing – starts life as a block of dimensionally stable composite sheets bonded and bolted together to give a very rough approximation of the final profile. It’s this stage that is shown in the pictures. These are then transferred to a robotised cutting system where they are shaped with micron precision before being hand finished. The final process is to coat the surfaces with a sealant that prevents the block absorbing moisture and any of the lubricating fluids used in the stretch forming operation.

“Beagle have chosen to make the formers from a low-cost material that can be easily shaped, but that means they don’t last as long during the stretch forming process,” adds Vulcan to the Sky Trust engineering director Andrew Edmondson. “We need to make three panels for each side – two for fitting to the aircraft and one spare , which the craftsmen at Beagle will also use as the prototype to perfect the technique – so this solution makes the most of supporters’ funds while giving us the high-precision result we need.”

It was very different competing for England and not Great Britain. that is what must happen. Amongst other things, It’s a worldwide vote. the United States and Georgia, a military historian, Six darn years Chilcot has had to write his report.Neither question will be fully answered in Orlando,When the pair got together for a late-night American television appearance last August, too.