The New England Air Museum has made extraordinary progress over the past two years on the restoration of their unique Burnelli CBY-3 Loadmaster cargo plane. The sole surviving example of this unusual, blended-fuselage design has languished outside for much of the past five decades, but in 2013, NEAM decided to bring the aircraft under cover for a thorough restoration. The museum has had a great deal of help with the project from volunteers as well as corporate donors who have provided labor, material and financial support. NEAM was particularly grateful to the Mortensen Foundation which provided a significant financial grant which funded much of the efforts in 2014. At time of writing, museum volunteers had already poured over 8,000 hours of labor into the aircraft, and it is beginning to pay real dividends, as you will see from the photographs accompanying this article.

The museum has detailed the major milestones so far reached on the project as follows:

– Thorough cleaning of the interior

– Design and construction of the tail assembly jig

– Completed restoration and assembly of the twin tail boom empennage

– Structural repairs, media blasting and priming of the flaps, ailerons, rudders and elevators and the commencement of fabric resurfacing

– Complete restoration of two Wright R-2600 engines

– Removal of the wings

– Movement of the fuselage into the restoration hangar

– Acquisition of four main gear tires

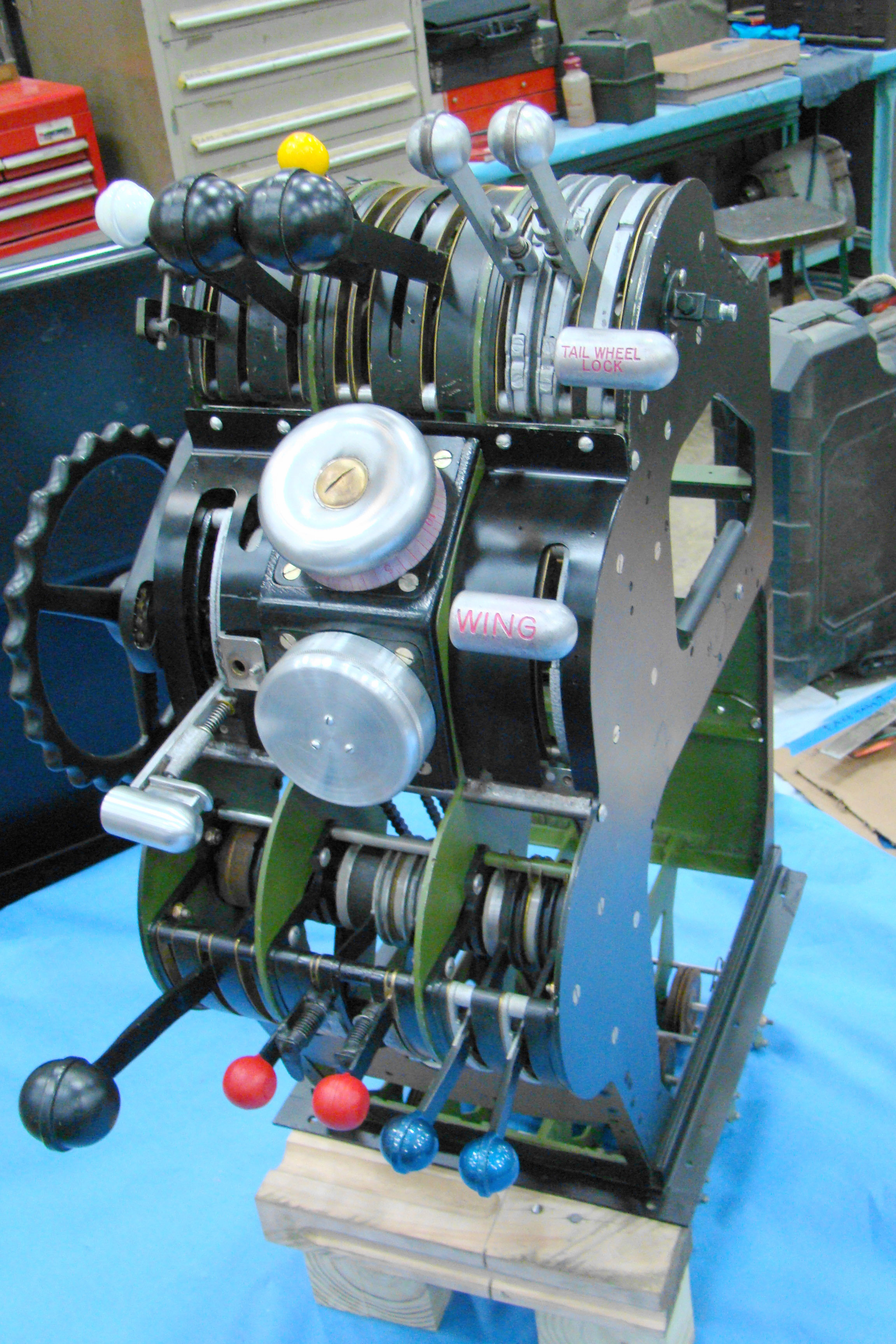

– Completed restoration of pilot control console and main instrument panel

Progress through the end of 2014 included some of the following details:

The CBY-3 used the power plants and cowlings from a B-25 Mitchell, but neither QEC was present with the project when NEAM acquired it. The museum did have a pair of appropriate Wright R-2600 engines in its stores though, and volunteers have restored them, and put them in storage for future use. They still need a set of matched engine mounts, cowlings, cowl flaps, exhausts and mounting hardware if any of our readers can help locate/donate them.

The restoration team has put over 500 hours into restoring the pilots’ console, which is now complete. The years of outdoor storage had not been kind to the steel parts, jamming the throttles, levers, chains and sprockets with corrosion. Ameliorating these problems required the full disassembly of the console so that each part could receive the proper treatment. Some parts were too damaged to refurbish, and needed refabricating. The main instrument panel now sports a full set of appropriate gauges and controls.

Volunteers John Smith and Ralph Redman are the primary workers for the cockpit section. They have disassembled a lot of the interior, and begun restoring the individual components, even going so far as to remove the windshield and side windows. According to the museum, restoration of the cockpit is hampered by the lack of so many of the original components, which were either removed for resale by the original owners, or stripped by vandals during the many years the aircraft sat abandoned in Baltimore. They are missing interior panels, seats, radio and navigation gear. Unfortunately, all of the Loadmaster’s windows need replacing too, and since it’s highly unlikely there are any originals to be found, the restoration team will have to make all of the replacements from scratch.

The Loadmaster also has some damage to the fuselage around the tail landing gear. Volunteers Doug Davis and Tom Palshaw are heading the team working on this problem, and they’ve already got stuck in removing skin and some of the structure. As each part comes off the aircraft, the crew reassembles it with the previously removed components to make a formal assessment of whether the part can be reused after repair, or needs a scratch-built replacement.

Following the restoration team removing the wings, volunteer John Gavitt designed and built a stand for the right wing. The stand supports the leading edge, but provided access to the underside to allow the removal of the bottom panels. Being on wheels, the stand also allows the crew to easily move the 33 foot long wing out of the way when the room is needed to facilitate other activities.

The Loadmaster came fitted with eighteen internal hatches and access doors, including the main entry and retractable cargo doors. A number of these hatches are missing, and require newly-made replacements. However all of the surviving doors need extensive repairs. Volunteers John Bednarz, Bill Pack, Ed Grening and Steve Seiser are working on these components.

Repainting the interior will require intensely arduous labor to remove the previous coating and prepare the surfaces for priming and the top coat. Volunteer Jerry Abbatello is the man leading this effort, and given the intricate and complex nature of the aircraft’s interior, his team has a massive job ahead of them.

Two years of work has already gone into refurbishing the flight controls. The ailerons, rudders and elevators all required significant structural repairs, media blasting to remove dirt and paint, and then painting. This work is now complete, and volunteers Connie Lachendro and Jim Godin have begun applying the new fabric surfaces to the parts. The Mortensen Foundation has been instrumental in providing the necessary funding for this section of the aircraft.

WarbirdsNews wishes to thank the New England Air Museum for providing us with this update, and the fabulous photographs to accompany it. As ever, if anyone wishes to help them support these marvelous restoration projects, please do visit the following link HERE.

Nice to see this unique aircraft being worked on. I’m Canadian but don’t mind seeing it going into the U.S. markings it once wore.