WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this past month!

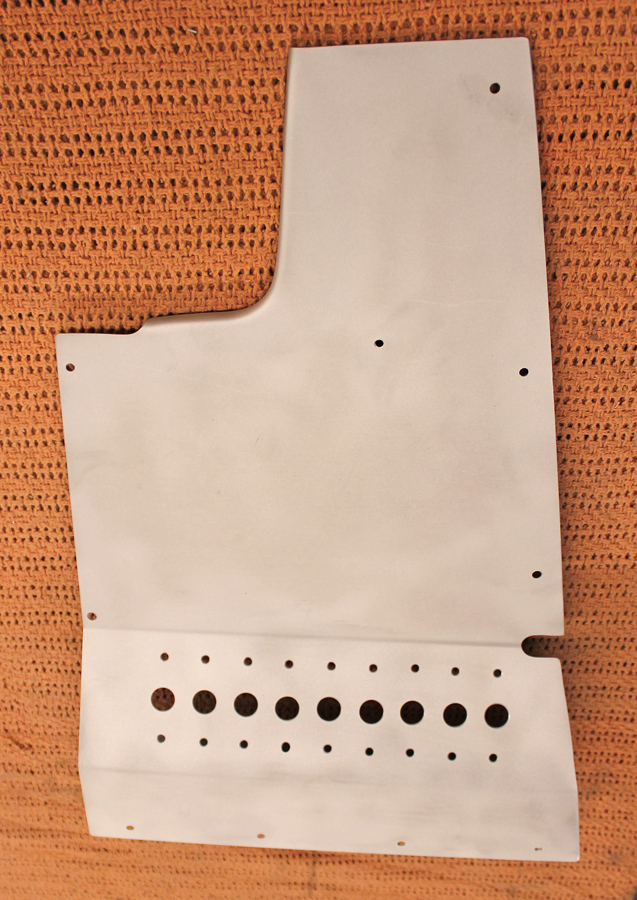

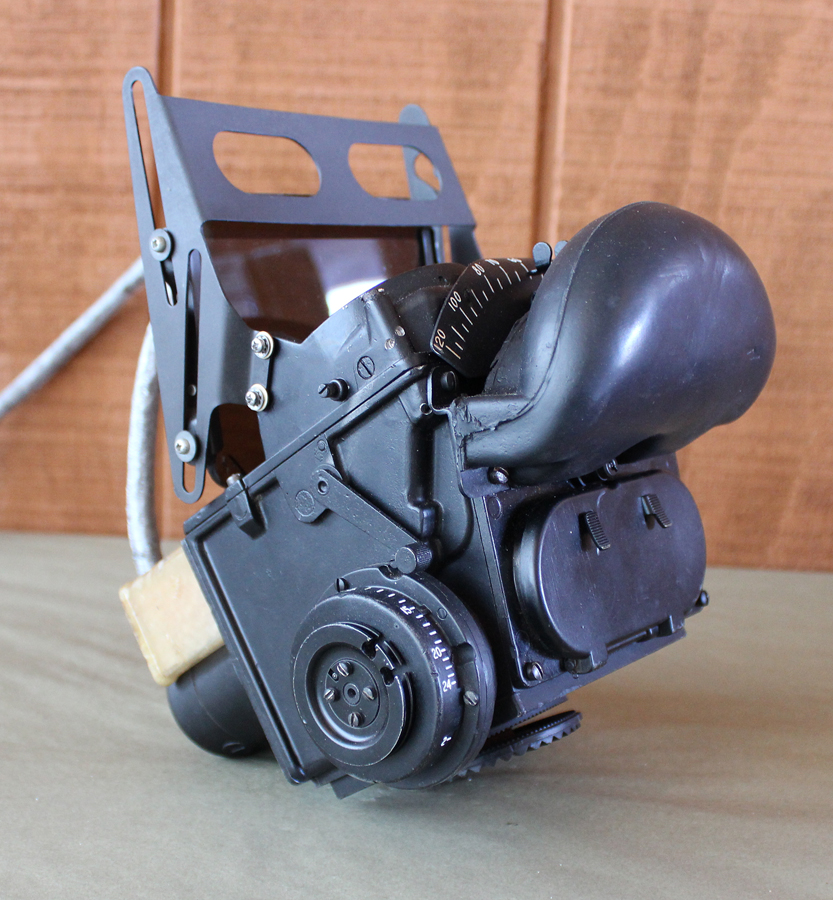

The team has been very busy this past month working to complete the hundreds of small “to-do” tasks that needed finishing, which included the gun sight, completing the 90˚ periscope for the gun strike camera, making heat and defrost, repairing or remaking electrical switch panels, bomb arming panels, fairings that surround the throttle quadrants, a second mounting panel for the oxygen quantity gauge, blinker and diluter valve mechanism, two induction trunk carburetor filtered air boxes, one last 28-volt power supply harness going to the circuit breaker panel, preliminary location for the shielded wiring of the microphone and headset jacks, modifying the shelf underneath the oxygen diluter mechanism to fit the new Garmin radio package, along with the avionics electrical harnesses, etc., etc., etc.

All of these cockpit panels, which Tom Reilly’s restoration crew had to repair or make new, have been shipped off to the printer for silk screening the correct verbage on each panel.

Garmin Radio Package

The project’s avionics specialist came to Douglas with the Garmin radio mounting tray and fitted it into the righthand cockpit underneath the oxygen diluter panel. With a small modification to one rib, the package slotted in perfectly. The microphone and headset jacks will mount in the original locations in the adjoining switch panel to the left of the Bendix Radio panel. And, in the co-pilot’s cockpit, they will mount in the original radio switch panel with the addition of one newly-drilled hole for the headphone jack.

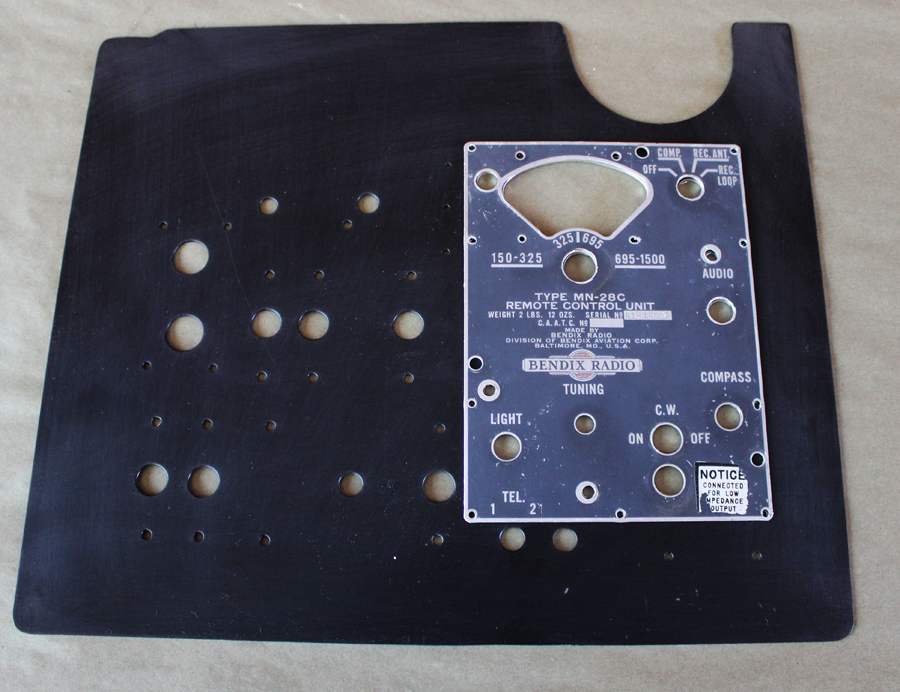

Bendix Remote Control Unit

With much searching, Weezie was finally able to locate this Bendix Remote Control Unit with a collector in California. An extremely rare unit, the last time the team saw one change hands was back in 2006. They were able to purchase this unit only with the express proviso that it was going to be installed in the XP-82.

Filtered Air Boxes

The last major work ongoing firewall forwards is the manufacture of the two filtered air boxes seen below. The rotating carburettor air valves located under the spinners have four selectable positions: ram air, hot air, half-hot air and filtered air. These are complicated boxes with many angles and shapes that hold the filters for cleaning the air. It will still take two team members about two weeks to complete and fit both units.

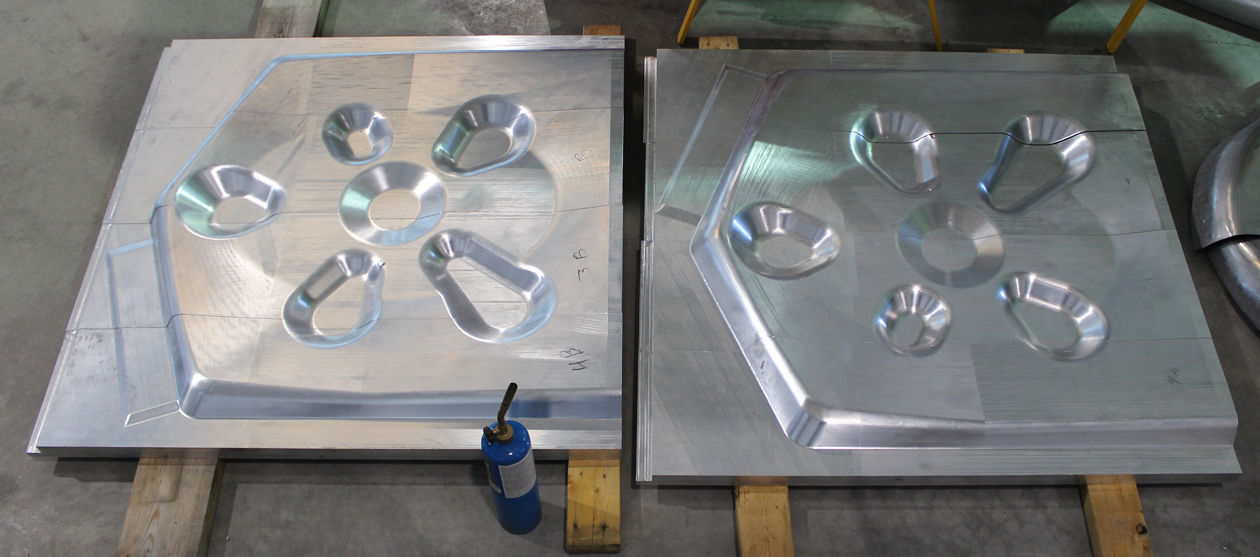

Internal Press Dies for the Main Gear Door Skins

The team’s machinist in Michigan has completed the two huge (350 lbs. each), mirror image press dies shown below, and personally delivered them to Douglas, Georgia on his trip to Florida. Tom Reilly did not want to trust these critical items to a shipping company, as they were very expensive to 3D design and machine, not counting the cost of the two 40” square x 3” thick aluminum plates. The team will take these dies to Atlanta to press-form the gear door skins as their own rubber press is not large enough to handle the exterior dimensions.

And that’s all of the news for January, 2017!

———————————-

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in March, 2017 for the next installment in the story following the XP-82′s road to recovery!

Be the first to comment

Graphic Design, Branding and Aviation Art