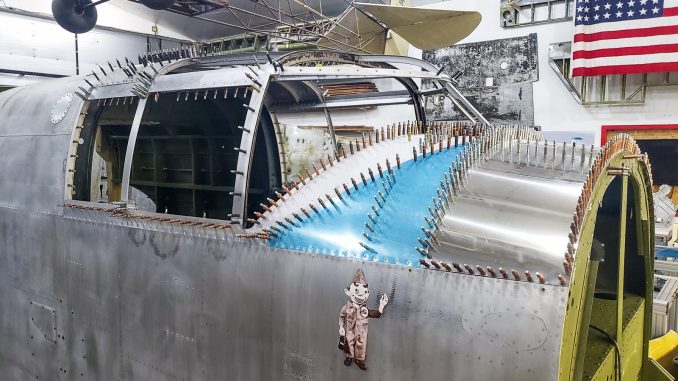

It’s been a while since our last report on the Warbirds of Glory Museum in Brighton, Michigan. As readers will recall, museum volunteers recovered the mortal remains of North American B-25J Mitchell 44-30733 from her longtime resting place, a sandbar on a river near Fairbanks, Alaska, during the summer of 2013 (this B-25 gained her nickname, The Sandbar Mitchell, as a consequence). The museum has made remarkable progress on both acquiring necessary B-25 parts, and restoring them, in the interim. This even included another Alaskan rescue mission to recover the battered wreck of a lend-lease B-25, abandoned in situ after a wartime mishap on its ferry flight to the Soviet Union. Perhaps more importantly, as a part of this process to restore the Sandbar Mitchell, the museum has also begun formally training the next generation of warbird maintainers/restorers via their Kittyhawk Academy. Indeed, other than preserving aviation history itself, nothing is more valuable to our small community than passing on the fast-vanishing skills involved with working on these vintage aircraft. Recently, our very own Moreno Aguiari contacted Patrick Mihalek, a founding partner in the Warbirds of Glory Museum, to help bring us up to speed on progress since our last article.

Current Accomplishments include:

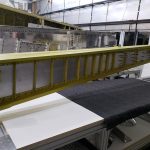

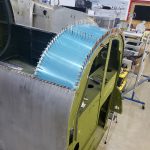

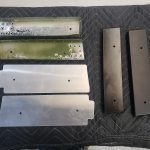

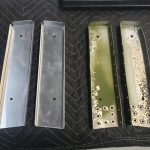

– Wing group, the empennage group and the landing gear assembly are all done

In more recent news, they had a visit from noted legendary restoration specialist Tom Reilly in February. An expert B-25-builder, having restored about a dozen examples in his career, Reilly noted that he was impressed with what they have accomplished. Having Reilly’s vote of approval was obviously a great boost to team morale.

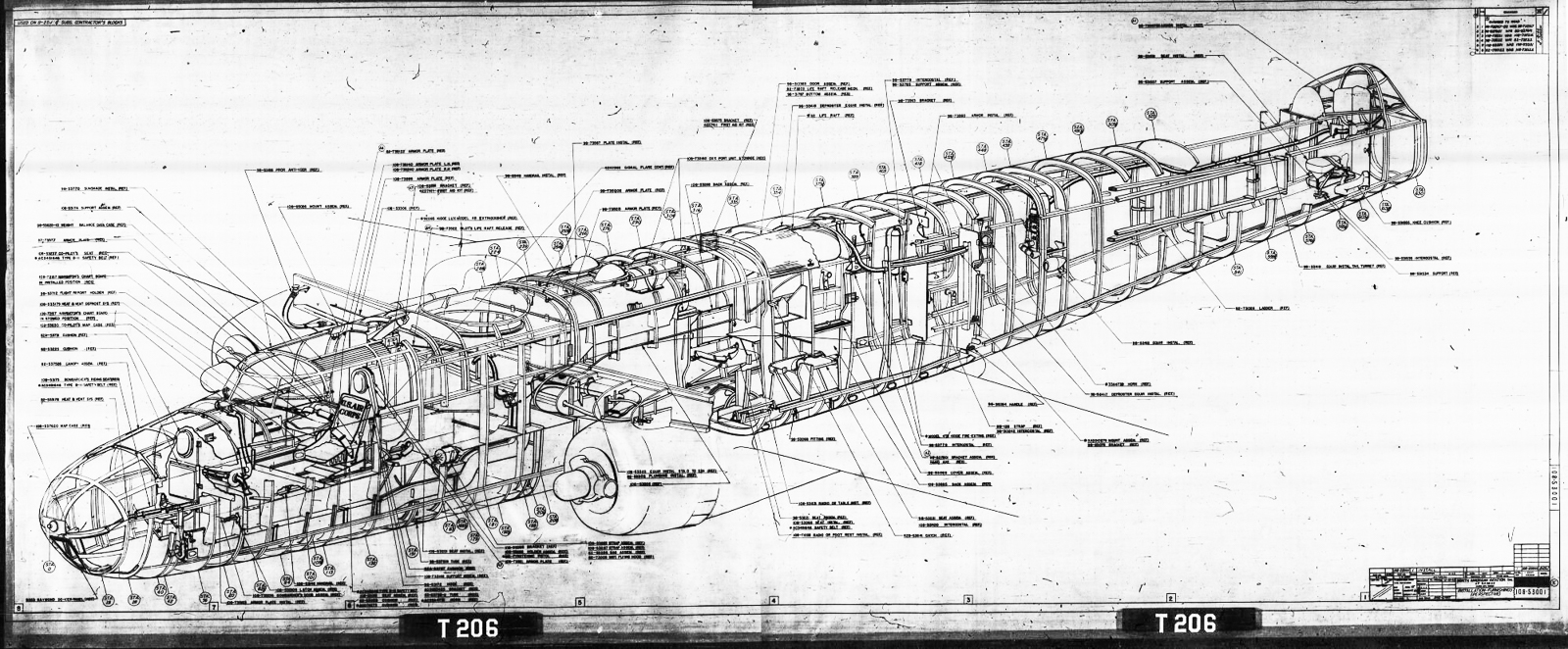

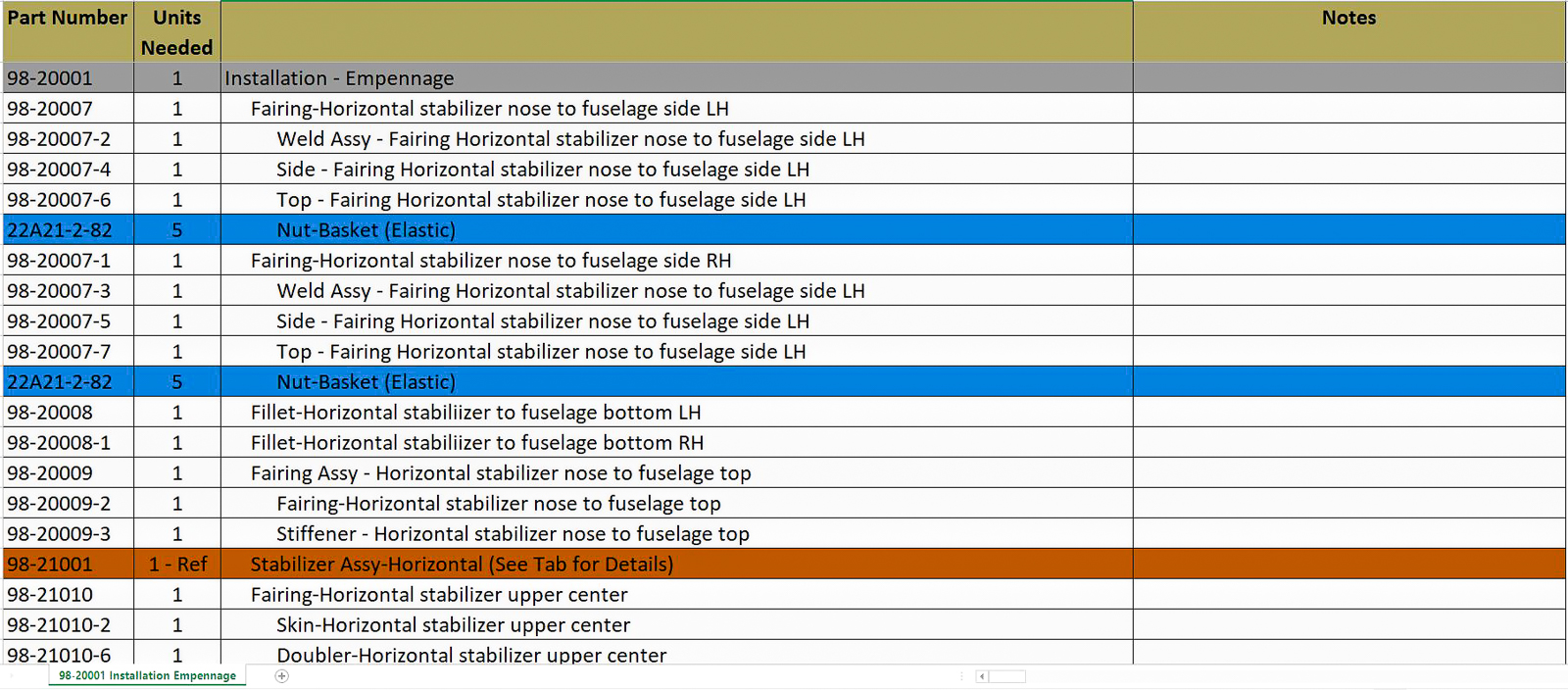

Unfortunately, however, the team has had to cancel their yearly fundraiser this April due to the global pandemic, so this has made fund-raising a little problematic. While the current health situation has made working in the shop impractical for the present time, they have been able to make progress from home on a lot of the planning and documentation which is so essential to any restoration project. As part of this, they recently noted: “While we can’t be in the shop working on the B-25, we are still making great progress from home on the computer. One of the biggest tasks with our restoration is making sure we have all of the necessary parts to build a flying B-25. Starting with drawing 108-00002 General Assembly, we are able to go through, drawing-after-drawing, virtually assembling the B-25 in Excel. From this Excel sheet, we are able to check against our inventory. So far to date we have almost 5,000 excel lines of parts, including the necessary hardware. We are very excited to be completing this task, which in turn will be a huge leap forwards in planning and getting Sandbar Mitchell in the air!”

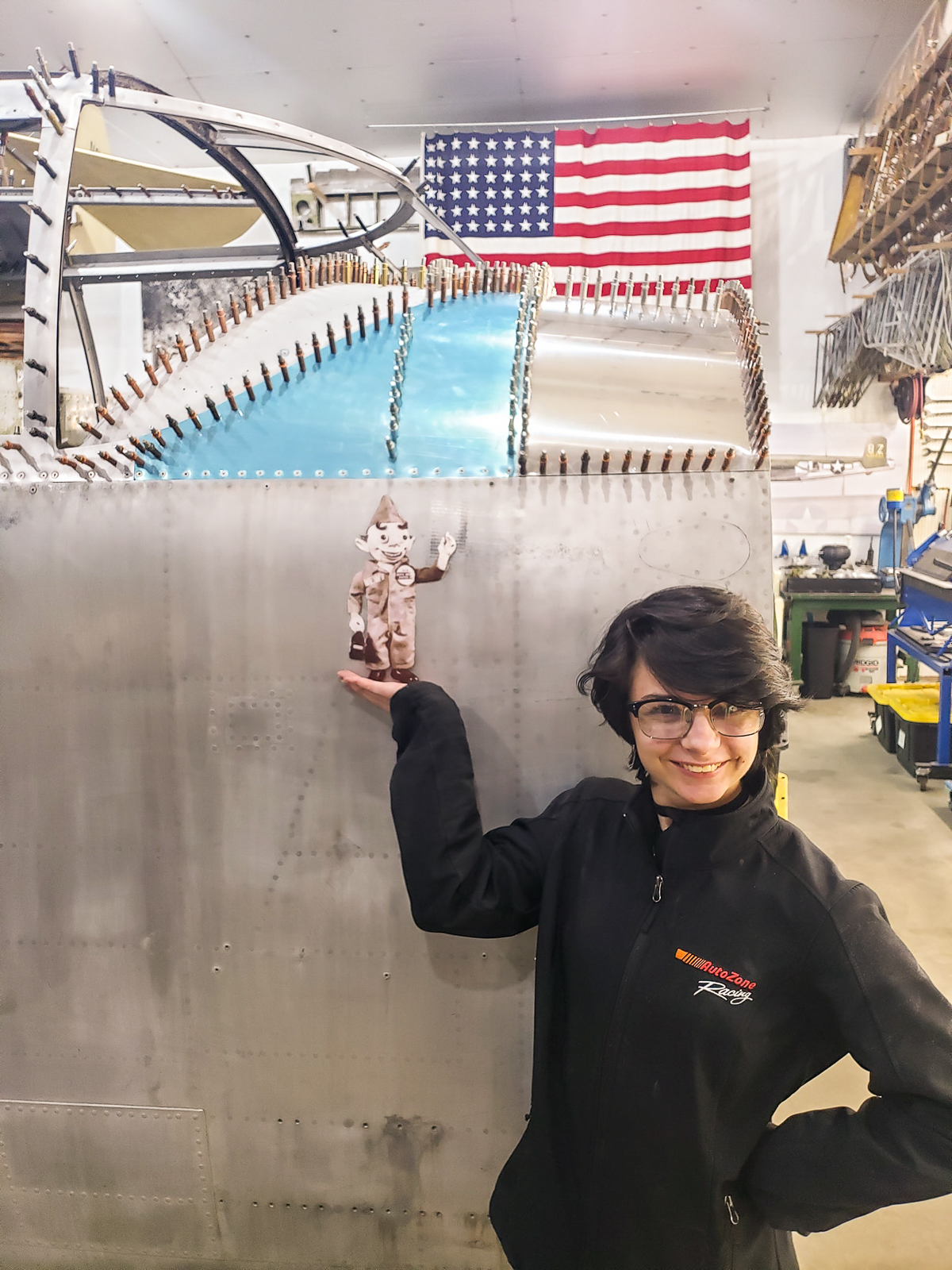

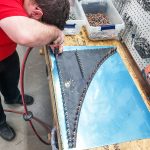

The Kittyhawk Academy has been a great success so far. At the moment, the academy has eight full-time students (aged 15+ years) working on disassembling parts, engine mounts, cleaning parts, and organizing inventory. At least one of their students, Katelyn Brooks, is going on to a future in aviation maintenance. Of Katelyn, the museum stated:“We are so proud of our student Katelyn! After getting involved in the restoration of Sandbar Mitchell she has decided to pursue a career in Aviation Maintenance and has been accepted in a local A&P school! Both rewarding to see progress being made on the B-25 and mentoring our nation’s youth in Aviation!” In a recent post on the museum’s facebook page, Katelyn herself noted that,“I’m gonna be working very hard, and I’m super excited to be doing this! I still find it funny that a few months ago I would’ve never seen myself doing this, but ever since I’ve started working on the B-25, it seems to have opened up a new passion and I just love going to the hangar, working on it and helping restore this beautiful warbird.” Brava to Katelyn for such a wonderful decision too!

The museum has a new board of ten directors to govern progress. They are representatives of the local community with diversified backgrounds.

- Put the rear spar section together

- Finish the top turret

- Finish the flight controls

This will of course be dependent upon how the pandemic situation unfolds in the months ahead, and financing will still be important. We wish this important group tremendous success in the future, and if anyone wishes to contribute, please do feel free to contact them, or click HERE to find out what you can do… They have some nice loot for sale in their online store as well! Additionally, the museum is currently… “running a campaign where if you become a new museum member, or re-new your membership, you will receive a free T-shirt. Also, we are giving our lifetime members one as a thank you.”

Be the first to comment

Graphic Design, Branding and Aviation Art