Hot for deHavilland Mosquito news following last week’s scrubbed first flight attempt for Bob Jens B.35 VR796 (bad engine starter apparently, with another first flight attempt possibly happening on May 26th), we have news from another Mosquito project – The People’s Mosquito. While up until now, most of the action has involved behind-the-scenes organizational issues, we have news that the team have actually started the rebuild. WarbirdsNews brings your their update here on what’s been happening lately!

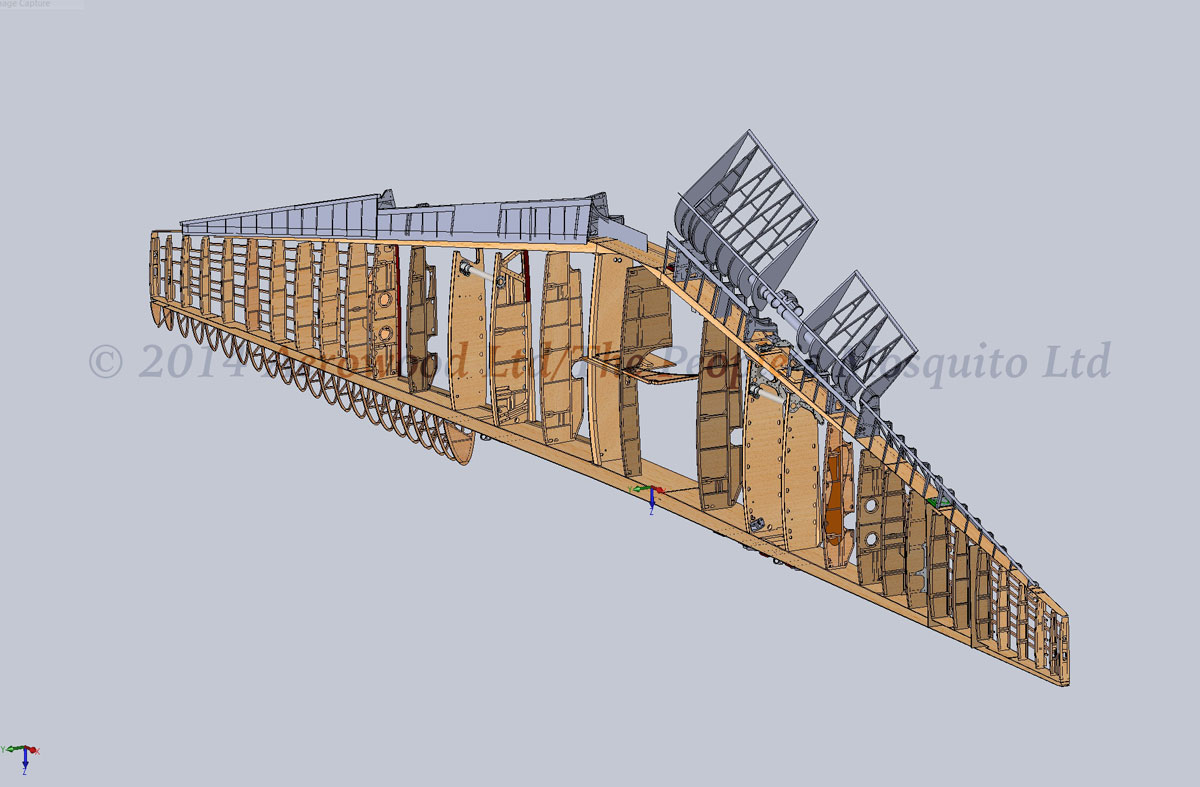

Construction is set to begin on the first set of wing ribs for The People’s Mosquito, RL249. Corin McCrae of Aerowood Ltd, will be cutting the ribs for RL249 at his workshops in Auckland, New Zealand in the coming weeks. There are various types of rib that make up the Mosquito’s wing, and these are fabricated from a variety of woods, both solids, such as Canadian Spruce, and plies. The Canadian Spruce that Aerowood will be cutting for RL249 is selected for aviation fabrication, and sourced and shipped to New Zealand from the same area on the west coast of Canada as that used by de Havilland Aircraft of Canada Ltd during WW2. Before being cut, it has undergone a number of tests to conform with air safety regulations.

Corin McCrae remarked on the quality of the Canadian Spruce, “It is the finest quality I’ve ever used for a wing”. The rib pattern cutting process used today by Aerowood is significantly different to that used when the Mosquito was being produced in the 1940s. Today’s process uses a Computer Aided Design (CAD) system and the cutting is computer-controlled. This makes for a cutting process that is much more precise and a lot faster than in earlier times, but combined with the original hand-finishing skills, results in an accurate build and reduces any production flaws.

Potential donors can visit the The People’s Mosquito’s Fundraising page HERE, where they will be able to choose from a number of options, how they want to donate. Donors will also be entered into the TPM Grand Launch Draw with the chance to win an exclusive key-ring, cut from the same Canadian Spruce as the wing ribs, and stamped with the logos of The People’s Mosquito and Aerowood Ltd.

Please click HERE to learn a little more about the People’s Mosquito from WarbirdsNews previous article on the aircraft.

What a brilliant idea