As many of our readers will be well aware, Avro Lancaster B.VII NX611 ‘Just Jane’ is under restoration with the Lincoln Aviation Heritage Center at former RAF East Kirkby in Lincolnshire, England. This Lancaster entered RAF service in April, 1945, but never saw combat during WWII. The French Navy/Aeronavale operated her from 1952, basing her on the South Pacific island of New Caledonia from 1958 until 1964. And here she probably would have stayed, slowly rotting into the jungle, had the Historic Aircraft Preservation Society not stepped in to save the Lancaster, and fly her back to England in an intrepid adventure from half way across the world in May, 1965. Sadly, HAPS wasn’t around for long, and NX611 made her last flight in June 1970. The aircraft went to new owners in 1973, ending up on the gate at RAF Scampton on loan for the next decade and a half. Fred and Harold Panton acquired NX611 in 1984. Their primary aim was to memorialize their late brother, Christopher Panton, who sadly lost his life while serving as an RAF flight engineer aboard a Handley Page Halifax heavy bomber during WWII. The Panton family and many volunteers have brought the aircraft up to ground-runnable condition over the past decade or so, but now they are working to restore their pride and joy to flying condition, with a hoped-for first flight sometime in 2020. Be sure to click HERE to help support their important work!

The following account is their most recent report, reproduced here with permission…

The Rivet Club – Newsletter 31

The team has made sterling progress this week and the addition of the contract staff has added extra manpower to the airframes team.

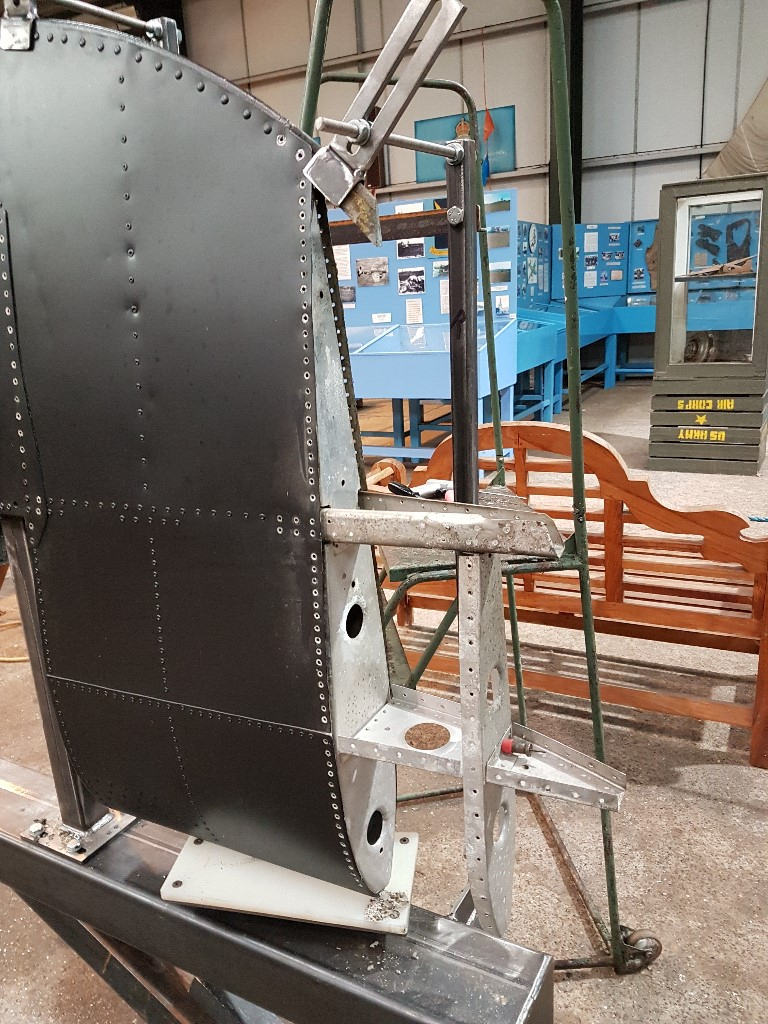

The first nose panels have been removed from the rudder to enable us to send two of the ribs away for fabrication. Through the survey last year, we knew that some of the ribs would need replacing so we had Cunningham Aero fabricate these during the summer, there’s just two left that we had no patterns for.

The team has also removed the access panels for the starboard trailing edge. This means that next week we will be able to start unbolting the trailing edge to remove it from the main plane. The trailing edge comes off in two sections, inboard and outboard, and the join is where the outer wing bolts to the main wing and fuselage centre section. Once the trailing edge is removed we can have it surveyed, fabricate some new panels and then rivet anchor nut strips on the structure to take the new panels. Historically these access panels are just pop riveted on but due to new inspection requirements these panel must be removed for inspection at every minor and major overhaul, so it is best to have them attached with screws as opposed to rivets.

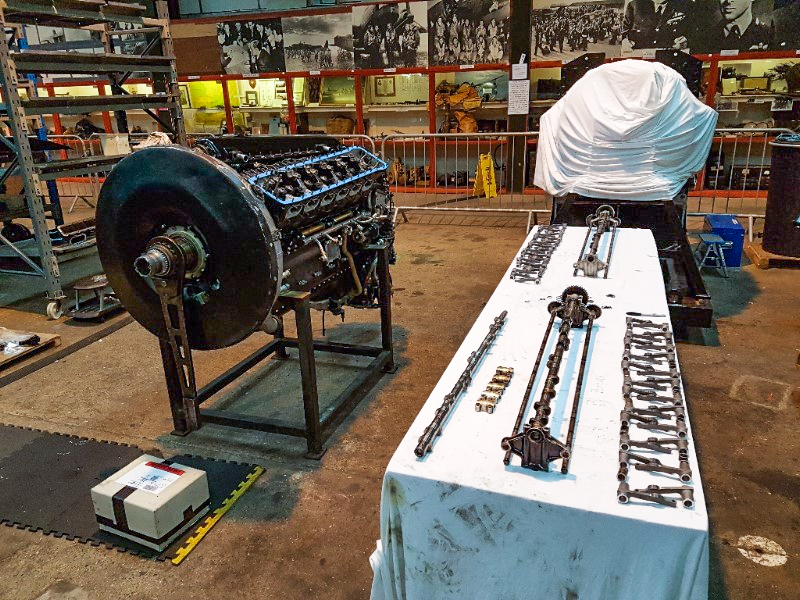

The engine team has finished the servicing for number 4 engine on the wing and number 3 engine on the powerplant stand. Number 2 engine is the spare that is being swapped, and will therefore only require minor servicing work. They have started on number 1 engine this week. All being well, the engine servicing will be finished next week.

The new number 2 engine is having its CRM’s built up by Keith and they will be refitted before the engine is remounted on the Lancaster. Once the CRMs are fitted we can lift the engine into place and plumb/wire it up.

Number 1 engine needs a little more work, which will mean the servicing will take longer, but the team has progressed through this aspect of the winter work very quickly.

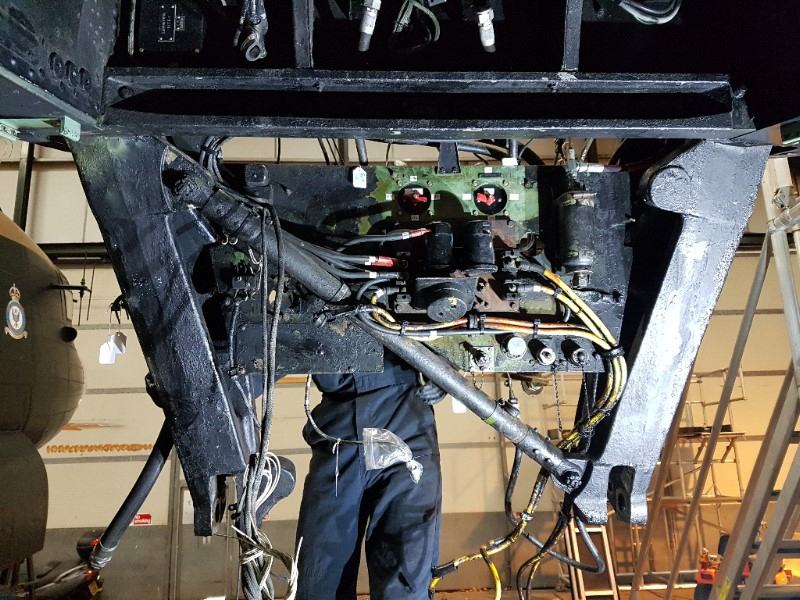

Bradley has been focussing his time on the undercarriage support beams. The aircraft has been jacked and the starboard undercarriage has been removed in one unit. The radius arms and hydraulic jacks have been removed to allow easy access to the wheel well and all of the attachment points which have SSI’s raised against them.

The priming panel has been removed from the starboard wheel well, as this attaches to the undercarriage support beam unit.

There are a lot of cables and control wires that thread through the undercarriage support beams, so these are all being labelled and disconnected.

More updates next week!!

Many thanks to Andrew Panton, and to the rest of the team at the Lincolnshire Aviation Heritage Center for providing this update. Be sure to click HERE to help support their work, and get the Lancaster flying again!

|

|

|

|

|

|

|

|

Be the first to comment

Graphic Design, Branding and Aviation Art