As usual, WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

Wings

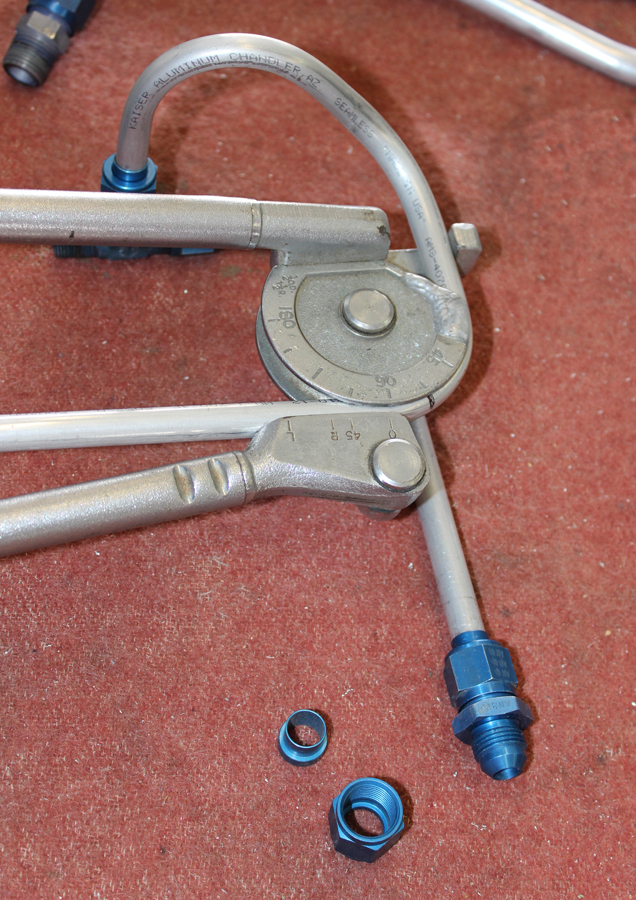

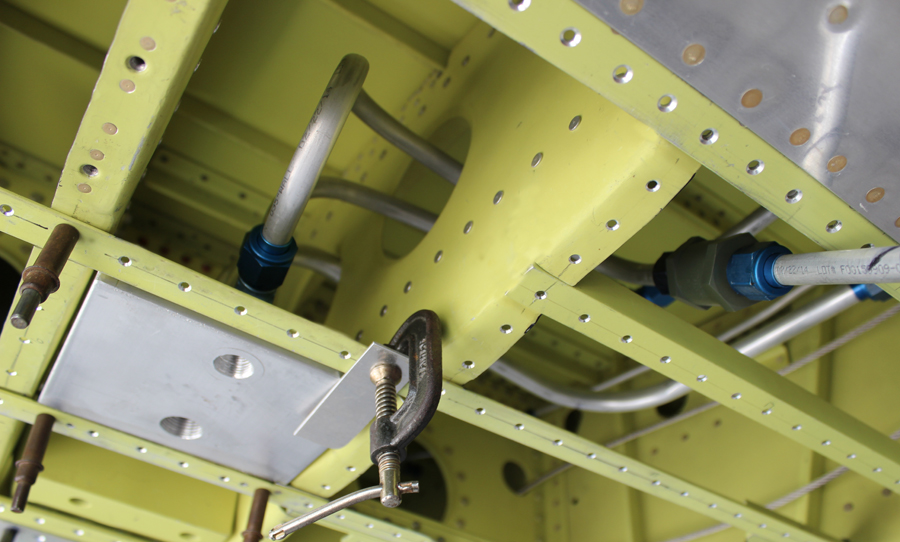

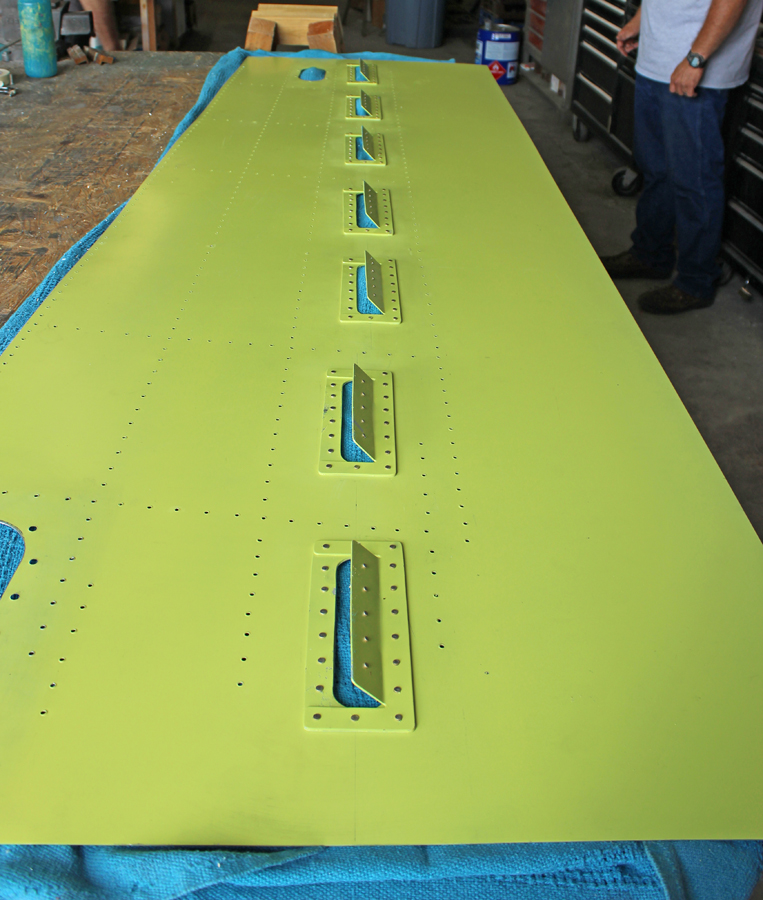

Many of finer details and fittings for each wing are now coming together: flap and aileron hinges, drop tank pressure and feed lines, de-ice hot air discharge vents (14 of them!), countersinking the remaining lower skins, aileron trim jack screws, etc., etc.

Vertical Stabilizers

Both vertical stabilizers are now finished with the exception of the side skins which must remain off at present in order to gain access for alignment and fitting during final assembly. The team has completed riveting the lower skins on for each vertical stabilizer. Both verticals await mounting to the horizontal stabilizer, and then the whole assembly will be ready for attaching to the aft fuselages. Reilly’s team has installed all of the trim tab (rudder and elevator) pulley brackets along with all of the closeout panel, fairing and tip nut plates. They have also completed the alignment, final installation and riveting of the four rudder trailing edge hinge points for each vertical stabilizer. The two aft jack points are now fitted along with the gap seal extrusions in the vertical stabilizer-to-rudder bays.

Vertical Stabilizers to Aft Fuselage Attachments

The special attach angles, all four of them, are now fitted to the aft fuselages. The team has drilled and reamed them for the attaching 5/16” and 3/8” nut plates and close-tolerance bolts. The team has flush-trimmed the excess skin overlap on both aft fuselages to accept the zero-tolerance butt-fit of the four vertical stabilizer side skins (two per tail fin).

The still unfinished attach angles for vertical stabilizers (in gray) on the rear fuselages. (photo via Tom Reilly)

Wheels and Tires

The new Michelin Air 32″ x 8.8” tires are now fitted to the new wheel rims. Reilly’s team had to manufacture two new inner-bearing and seal spacers using a lathe to cut them from a single aluminum billet. None of the original ones that came with the XP-82 project from Walt Soplata or the Alaska wreck site were salvageable due to deep rust pits.

Heat Exchangers / Cooling System

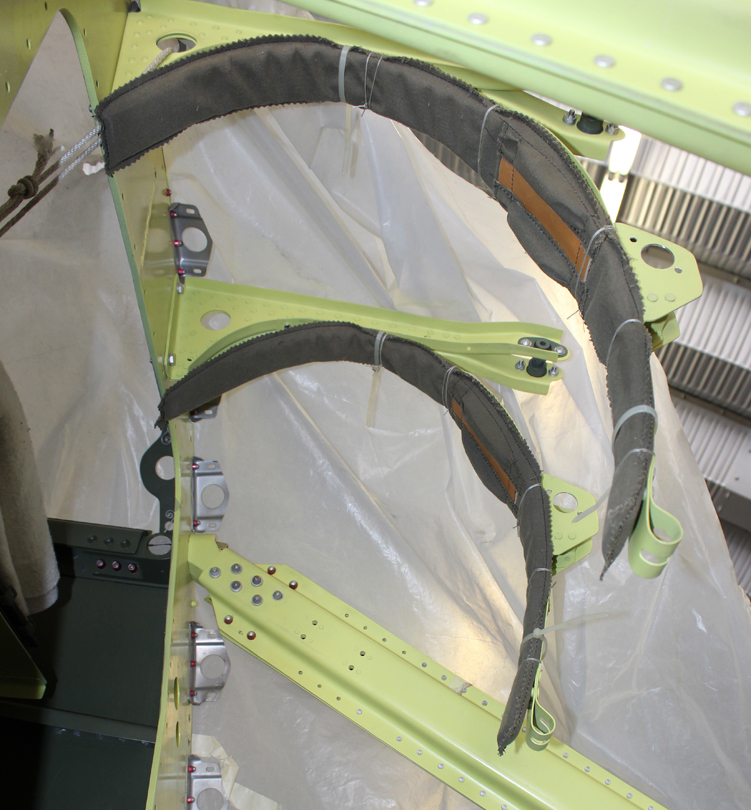

One of the subcontractor machine shops has completed the remainder of the brass water neck and purge fittings that will be soldered on to the shell(s) of each heat exchanger. (For a size reference, the diameter of the large flanges is about 6”.) Another subcontractor has completed sewing the chafe straps (10) which protect the oil and glycol header tanks.

Windshields

As mentioned in the previous news release, the two center windshield glasses are now complete and fitted into their frames. The four side glasses are with an aviation Plexiglass-forming company in Ohio. The team hopes to have them back soon.

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early August for the next installation following the XP-82′s road to recovery!

Please click HERE for some of our previous updates.

1 Trackback / Pingback

Graphic Design, Branding and Aviation Art