When the wings and empennage were finished, however, they were of better quality than wartime-manufactured examples. “We used epoxy glues…we had to get special approval for that. We filed a 337 form [with the FAA] as per the inspector’s recommendation.” Also, the restoration team had the benefit of time to determine the wear patterns and locate stress cracks on the airframe. “We had the advantage of fifty years of use and abuse by students and civilians to see what the weak points were.” With FAA approval, the team modified these weak points. And, unlike the original finish, the bare wood surfaces didn’t receive coats of regular varnish, which would split and peal, but instead a lathering with Stits epoxy varnish. The team covered this with Stits poly-fiber, then doped and painted it with several coats of Imron. Perhaps the biggest problem during the restoration process though was overhauling the cracked landing gear struts. According to Greg, it was just a “by-product of the age of the airplane, the design of the landing gear…these airplanes were never meant to last for 50 years. We went to a Fairchild fly-in where there were about a dozen Fairchilds. Dick Schaus (Director of Restoration & Maintenance) and I crawled underneath each one and found out that they all had the cracks we were finding. Greg tried to repair the gear and was successful in doing so, but the heat treater over treated them and in the process caused the cylinders of the oleos to go out-of-round.

The team located four pairs of undercarriage, and tested them for cracks using a magna-flux machine. They rejected each set. Then, while Greg was in Missouri on an aircraft recovery mission, Schaus got a call from a man who heard of the restoration’s problem and had a set of New Old Stock gear from the 1940s. They still had the manufacturer’s yellow tags on them. Incredibly, the man lived only 10 miles from where Greg was picking up the recovered aircraft!

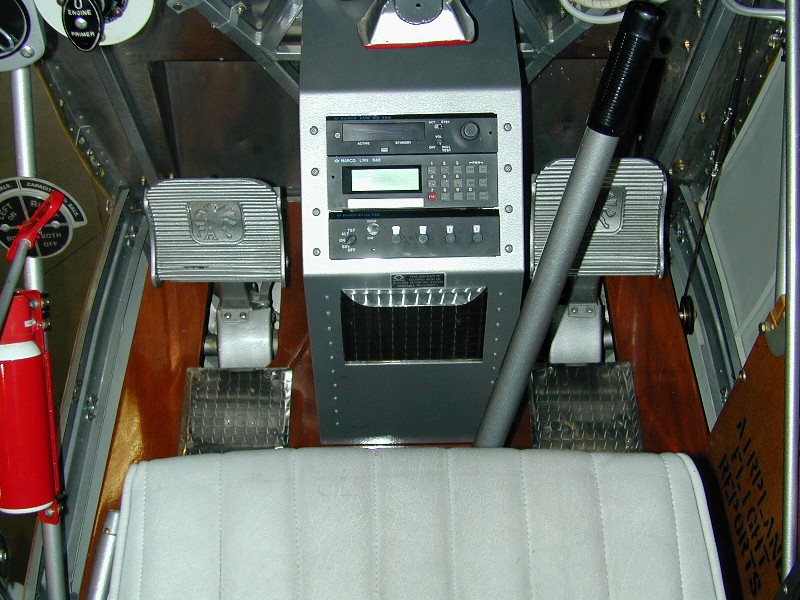

There were many, many other problems that the restoration team faced, but they rose successfully to each task. They added new Cleveland brakes, new up-to-date avionics and electrical systems, an electric starter, transponder, Loran, intercom, up-to-date seat harnesses, and dozens of other items. Since this was going to be a flying aircraft, it had to be a safe aircraft. (CLICK BELOW FOR THE NEXT PAGE).

Thanks for sharing, great story.